Print and Apply labeling

Markem-Imaje 2200 Print & Apply Labeling Machines

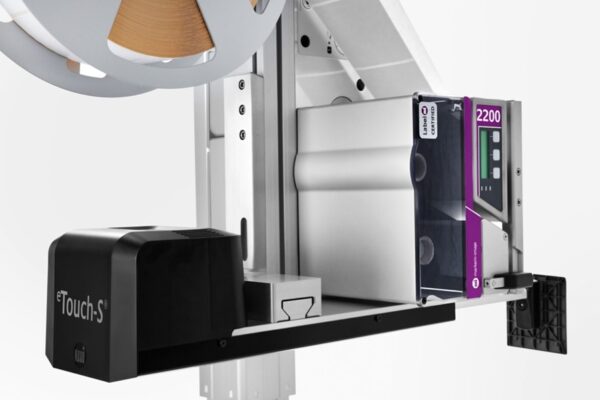

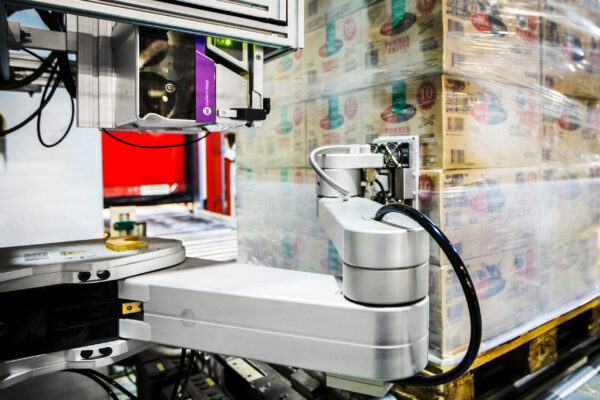

The Markem-Imaje 2200 Print & Apply Labeling Machines are designed to improve label efficiency in any production line. The 2200 series is built on a proven concept, providing reliability, efficiency, and ease of use to minimize coding errors. Featuring advanced features such as eTouch-S® intelligent applicator, the 2200 series takes print and apply to the next stage of evolution, providing a wide range of interchangeable applicators, optimized operational intervention, and unparalleled application rates.

Key Features

- Operator Panel: With a simple graphic operator panel, users can quickly and easily access relevant operational data. For a higher level of functionality, an optional color touch screen production interface is also available.

- Long Media Lengths: The 2200 series supports longer media lengths for extended operation and synchronized media reloading.

- Unmatched Reliability: The 2200 series offers compliant ANSI grade A/B codes, even at the highest application speeds. An integrated barcode scanner ensures that 100% of cases leave the factory with a readable barcode.

- Simple Routine Maintenance: With the ability to exchange wear parts and no need for complex calibration or tools, the 2200 series offers a simple routine maintenance regime.

- Versatile Applicators: The 2200 series offers a wide range of applicators, best suited for each application, minimizing the need for line changes and expensive modifications.

- High-Performance Printing: The eTouch-S® applicator utilizes artificial intelligence to prevent labeling errors, protect products, and increase uptime. The in-built auto-change/tandem functionality ensures constant and consistent label management with automatic label tension and integrated label control.

- Wide Range of Label Sizes and Materials: The 2200 series supports a wide range of label sizes and materials, including die-cut self-adhesive labels, label stock outside wound as standard, 178mm maximum label width, and 350mm maximum label roll.

- Multiple Print Engines: Featuring multiple print engines with individual programmable counters, graphic display, and machine status in local languages. Additionally, the 2200 series supports multiple print methods, including thermal transfer or direct thermal, selectable on the same print unit.

- Connectivity: The 2200 series supports Ethernet, high-speed RS-232, 2 x In via Opto 5 x Out via relay (24 VDC), 300-115 200 bps, USB support for back-up/restore and label upload compatible with Weihenstephan standard Dual Language Support (DLS): Markem-Imaje LabelPoint, and ZPL emulation.

- Environmental Friendly: The 2200 series is designed to be over 95% recyclable.

2200 Series Specifications

- Printing Methods: Thermal Transfer or Direct Thermal (selectable on the same print unit

- Print Engines: 56mm – 168mm (200/300 dpi)

- Maximum Print Speed: 300 mm/s

- Fonts: 16 smoothly scalable fonts, TrueType font downloading, Unicode font support

- Graphics Features: Supports all major linear and 2D barcodes

- Maximum Label Width: 178 mm

- Maximum Label Roll: 350 mm (optional 400 mm)

- Ribbon Length: 660 m

Operating Conditions

- Temperature Range: 0°C to 45°C

- Humidity: 20% to 85% non-condensing

- Power Requirements: 240 VAC; 50/60 Hz

- Air Pressure: 6 bar

Applicators

- The eTouch-S® applicator provides complete motion control and application diagnostics thanks to its unique SoftTouch technology

- Blow, Enhanced Wipe, or Flex SE: for top, side, and front application

- High-speed front application

- Corner wrap for dual adjacent side application

Contact Us

Contact us today to learn more about our Markem-Imaje 2200 Print & Apply Labeling Machines. Visit www.markem-imaje.com/docs/default-source/product-brochures/hq/2200-ds-hq-h1-markem-imaje.pdf to download a brochure and find out how our state-of-the-art labeling machines can be used to optimize your production line and improve overall efficiency.