Pallet stackers

Palomat – for automatic stacking and destacking of pallets.

- Protects employees from injuries that can occur when manually handling pallets.

- The backs, legs and hands of employees are healthier, their working position is better and they do not have to lift heavy loads.

- Pallet handing as well as manufacturing operations are more effective.

- Pallets brake less often.

- Warehouses are significantly cleaner and more ordered – pallets are correctly stacked.

- Since pallets get „tossed around” less, there is less undesired noise in the work area.

Palomat Greenline

Automatic single pallet stacking and destacking at floor level. Only uses electricity for power (230 V). An economical machine with low energy consumption. Standard model for 15 or 25 pallets (EUR and FIN pallets). A -25°C temperature-resistant version and solutions for non-standard pallets are optionally available.

Palomat Flexomatic

Automatic single pallet stacking and destacking at floor level. Standard model for 15 or 25 pallets (EUR and FIN pallets). Solutions for non-standard pallets. The control panel is logical and easy to use. Flexomatic works with electricity and compressed air.

Colour options:

RAL 3002 red

RAL 5002 blue

RAL 7032 grey

RAL 7035 grey

You can find more information on Palomat products HERE.

Take a closer look: PALOMAT Stand Alone series

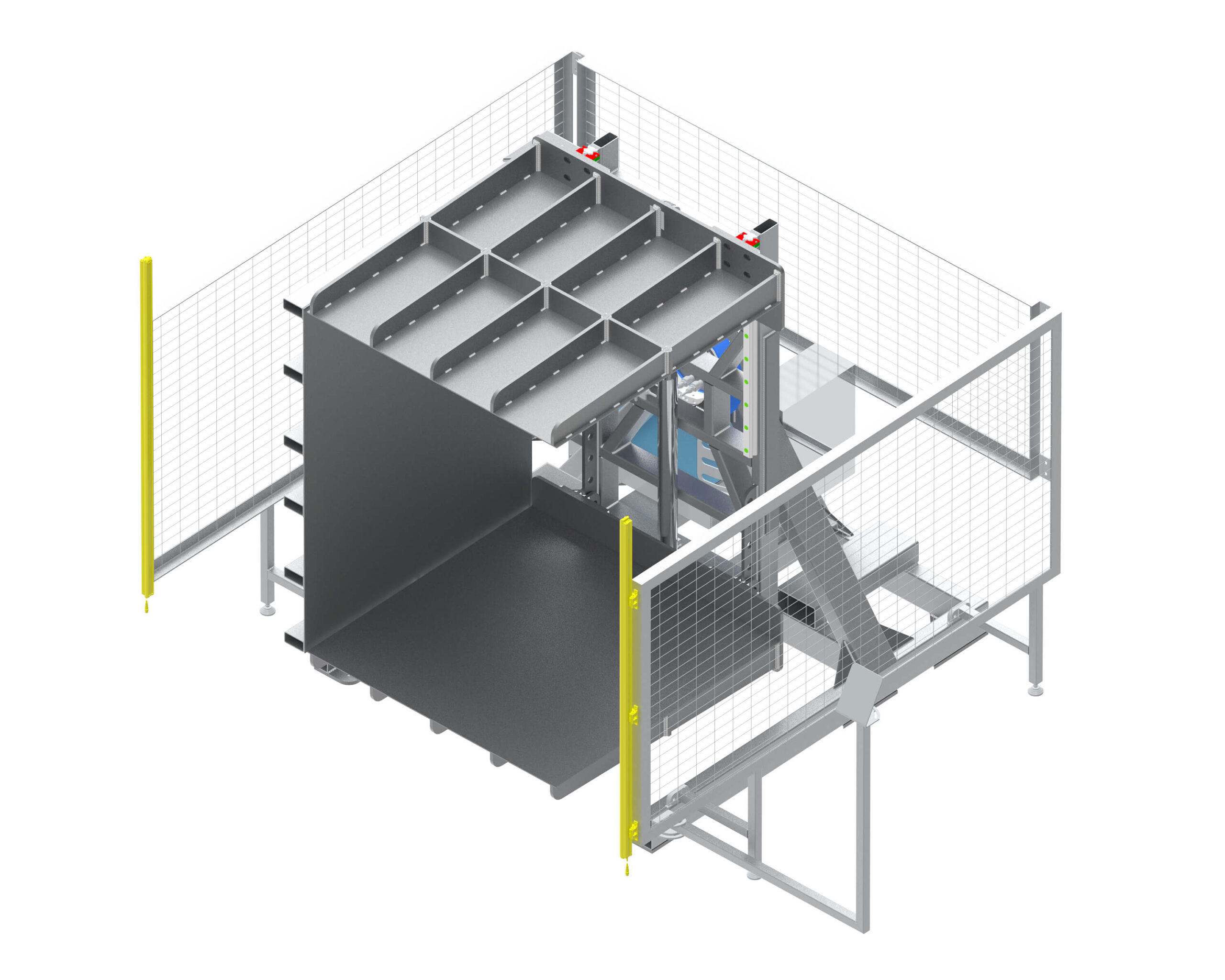

Pallet changers

Depending on the environment, the transport of products requires pallets made from different materials. A pallet changer allows to change a standard wooden pallet for a plastic, aluminium or composite material pallet or vice versa. A pallet changer also allows to replace broken or soiled pallets.

Operating principle A:

- Unwrapped pallet

- The pallet with the goods it is loaded onto the pallet changer using a scissor lift or stacker

- The new pallet is laid on the existing goods

- The goods are turned 180 degrees

- The old pallet is removed from the top and the goods are lifted off

Operating principle B:

- Wrapped stable pallet

- The pallet with the goods it is loaded onto the pallet changer using a scissor lift or stacker

- The goods are turned 90 degrees

- The old pallet is replaced with a new one

- The goods are turned back upright and then lifted off

Standard product:

- Carrying capacity: 2000 kg

- Outer measurements (without control unit, length, width, height): 2350 x 2500 x 2150 mm

- Weight: 2500 kg

- Measurements of the loading area (length, width, height): 1200 x 1200 x 1550 mm

- Movement range of the moving table: 700 mm

- Adjustment range of the stationary table: 400 mm, in 100 mm steps

- Supply voltage: 400 V, 50 Hz, 3 phase

Pallet wrapping

In Estonia we represent the company Atlanta Stretch, which is well known for its innovative solutions and it is among Europe’s leading manufacturers of pallet wrapping systems.

Automatic pallet wrappers

Omega – a rotating ring pallet wrapper with an operating speed of 120+ pallets per hour.

Revolution – a rotary arm pallet wrapper with an operating speed of up to 80 pallets per hour.

Mytho A – a rotating ring pallet wrapper with an operating speed of up to 30 pallets per hour.

Semi-automatic pallet wrappers

Sfera – a battery-powered pallet wrapping robot.

Mytho – a pallet wrapper with a unique and maintenance free design.

Synthesi – a cost-effective pallet wrapper for smaller manufacturers and warehouses. Also suitable for pre-stretched and coreless wrapping film.

You can find more information on Atlanta Stretch products HERE.

Mobile robots

We offer Global AGV automatic guided vehicles from the Danish manufacturer Bila. The Global AGV technology is easily integrated into existing operations and environments without the need to significantly alter the existing operations and layouts of the enterprise.

The AGV navigates using a 360° laser system that constantly detects the environment so the AGV can follow a pre-planned route. If your logistics flow changes, then the system’s great flexibility allows you to change the route easily and to map based on new needs.

We offer GoPal automatic guided vehicles from the Danish manufacturer Robotize. GoPal has a large product offering and fully CE certified solutions for the automation of internal pallet logistics in factories and warehouses. These autonomous collaborative robots have been developed and are approved for safe collaboration with humans and can handle various pallet types with various loads.

GoPal provides a fully integrated solution with robots, pallet stations and software, which can be installed and integrated within days and which requires almost no alterations to the installation site or lengthy operator training. GoPal’s solution will become profitable and starts saving money in about 4–18 months, depending on the wage level and work planning.

A SAFE AND GOOD WORK ENVIRONMENT

The GoPal solution will make the working environment significantly safer, by eliminating the accidents and hard work related to the use of forklifts and manual handling of pallets.

EASIER ADMINISTRATION

Thanks to the GoPal solution there will never be a need to plan shifts or to look for replacements. Collaborative robots will never take sick leave or vacation days.

DATA & COMMUNICATION

With GoPal you can gather valuable data on internal pallet logistics, which can be used for optimising work operations. The system also communicates directly with ERP/WMS.

MINIMISING THE COSTS ASSOCIATED WITH HUMAN ERROR

Forklifts and manual pallet handling sometimes leads to destroyed goods, materials or items and can also damage a building’s infrastructure. GoPal minimises all the costs associated with that.

You can find more information on Robotize products HERE.

Take a closer look: Robotize brochure

Contact us

After the message has been sent, you will receive a confirmation message in your inbox when it has been successfully received. If you do not receive such a message, please contact us at info@proven.ee.