Pallet wrapping

In Estonia we represent the company Atlanta Stretch, which is well known for its innovative solutions and it is among Europe’s leading manufacturers of pallet wrapping systems.

Automatic pallet wrappers

Omega – a rotating ring pallet wrapper with an operating speed of 120+ pallets per hour.

Revolution – a rotary arm pallet wrapper with an operating speed of up to 80 pallets per hour.

Mytho A – a rotating ring pallet wrapper with an operating speed of up to 30 pallets per hour.

Semi-automatic pallet wrappers

Sfera – a battery-powered pallet wrapping robot.

Mytho – a pallet wrapper with a unique and maintenance free design.

Synthesi – a cost-effective pallet wrapper for smaller manufacturers and warehouses. Also suitable for pre-stretched and coreless wrapping film.

You can find more information on Atlanta Stretch products HERE.

Orbital wrappers

Orbital wrappers are primarily intended for the packaging of long products in order to protect them from dirt, dust and moisture during transportation and storage. For instance casings, furniture parts, doors, etc. It is possible to package products of different lengths, diameters and shapes. The machines can be either semi-automatic or fully automatic. Packaging takes place significantly faster than manually and saves labour.

Box wrapping

The main purpose of a traysealer is to preserve and to protect fresh or processed foodstuffs by sealing these into pre-fabricated boxes (by sealing the box with film). Traysealers are either semi-automatic or fully automatic, depending on requirements and packaging speed.

Semi-automatic traysealers

Depending on the shape and size of the box, semi-automatic traysealers can package up to 24 boxes per minute. It is also possible to use modified atmosphere packaging (MAP). Different materials are available for packaging: PP, PS, C-PET, A-PET, cardboard, aluminium, etc.

Fully automatic traysealers

Fully automatic traysealers can package up to 240 boxes per minute and the machines can also be used for modified atmosphere packaging (MAP). Box delivery to the machine and product dosing into boxes can also be automated, boxes can optionally also be closed with lids. Fully automatic traysealers offer many possibilities for packaging and every project needs to be approached based on the product and the box as well as the packaging speed requested by the client.

Thermal forming machines

Thermal forming machines package very different products by producing packages specifically designed, formed and cut for a specific product. They are mainly employed in the food industry – meat, fish and cheese packaging. Thermal forming machines can also be used for skin packaging where the film is formed tight around the contours of the product (for instance meat products – sliced ham, etc.), as well as for vacuum packaging of non-food items.

The operating principle of the machine is based on two film rolls (an upper and a lower roll), from which the machine forms the packaging, welds the film, cuts and separates the packages and collects any leftover film.

The process:

- The lower film is unrolled from the roll.

- The lower film is heated and formed in the forming area.

- The formed packages move on to product insertion (manual or automatic product insertion).

- The upper film is unrolled from the roll.

- In the welding area the product is packaged in a vacuum or modified atmosphere packaging (MAP), as needed, and the upper and lower film are welded together using heat and pressure.

- The packages are cut and separated (crosswise and longitudinal cutting).

- Finished packages are transported out of the machine.

Thermal shrink wrap machines and shrink tunnels

Thermal shrink wrap machines use a film that shrinks tightly around a product through the application of heat.

There are various thermal shrink wrap machines:

- Heat shrink chambers

- Semi-automatic or fully automatic shrink tunnels

- Sleeve wrapping machines

The most common shrink film is polyolefine, which is available in various thicknesses and sizes. Other materials used include PVC, polyethylene, polypropylene, etc. The machines use shrink film in the form of a sheet or half-sleeve (the film is folded in half at the centre). It is also possible to use heat shrink wrap bags. There are many products that are packaged using thermal shrink wrap machines – books, various boxed goods, foodstuffs, transport packaging, etc.

Semi-automatic thermal shrink wrap machine with shrink tunnel.

Suitable for packaging various products, including foodstuffs.

Shrink tunnel

Automatic thermal shrink wrap machine.

Suitable for packaging various products.

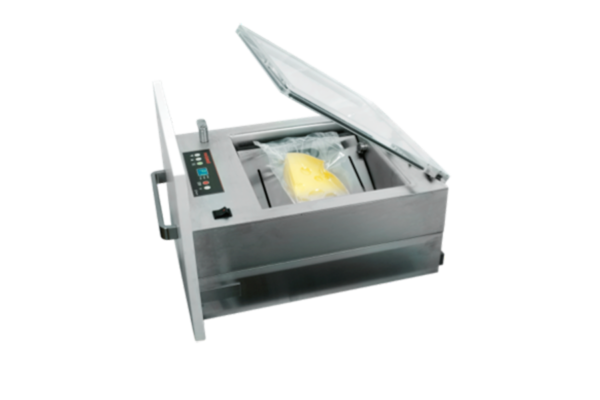

Vacuum sealers

Packaging food using vacuum or modified atmosphere packaging (MAP) increases its shelf life several times, protects the food from bacteria and preserves its flavour properties.

The organoleptic properties of vacuum packaged food are preserved, food does not dehydrate, flavours and colours remain vivid. For certain foodstuffs, getting the best results requires the removal of all air and adding a gas mixture. The gases used mostly are nitrogen and carbon dioxide, but also oxygen, argon, dinitrogen oxide. A gas atmosphere helps to preserve the food and prevents its mechanical breakdown.

Vacuum sealers with modified atmosphere packaging (MAP) are available as manual, semi-automatic and fully automatic, table top and standalone models depending on need and the necessary packaging speed.

Other film sealing machines

We offer Polystar film sealing machines from the German manufacturer Rische+Herfurth Gmbh You can find more information in the brochures below:

The RoRo StretchPack packaging machine from the Danish manufacturer Tentoma uses a unique method for packaging large-sized pallets and products. Time-consuming and troublesome packaging is a thing of the past. The machine uses stretch wrap for packaging and stretches it around a pallet or product.

RoRo StretchPack is suitable for all industries and the standard XL size machine can package goods sized up to 1300 x 1400 mm, pallet length 6000–8000 mm depending on the thickness of the stretch wrap.

There are two options for ensuring ventilation – to leave holes in the welds or to make holes in the stretch wrap under the packaging.

The machine has the following advantages compared to other similar packaging methods:

- 100 % wrapped products

- 100 % automatic in-line or separate packaging of various sized products

- automatic selection of stretching strength and wrapping sleeve

- high quality packaging (printed wrapping film)

- low energy cost (no heat and/or gas shrink tunnels)

- optimal wrapping film use

- great reliability

- low maintenance requirements and TCO

The RoRo StretchPack packaging machine can be made to be very flexible, for packaging various sizes of pallets and even allow to mix sizes – it is also possible to use three different sizes of stretch wrap an the machine will select the wrapping strength and the wrapping sleeve automatically depending on the size of the pallet. Pallets of different length are no problem either – the stretch wrap used is tubular in shape and a sufficient length is unwound from the roll depending on the length of the pallet. All wrapping films can be printed. The ends of the wrapping film tube can be welded and the result is a completely sealed packaging.

Contact us

After the message has been sent, you will receive a confirmation message in your inbox when it has been successfully received. If you do not receive such a message, please contact us at info@proven.ee.